| home | order | prices | models | features | options | gallery | reviews | for sale |

Started March 2008

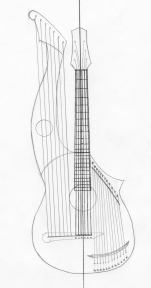

A musician caught the harp guitar bug while attending the 5th annual Harp Guitar Gathering (HGG5) in Oct 2007 and contacted me about building a custom harp guitar.

I had built another harp

guitar similar to the one in the sketch that we used as a starting

point for the new design. Over several weeks the design evolved

thru several iterations. We mailed sketches back and forth. Here

are some of the concepts we considered:

We decided to use Englemann spruce for the top which is not available in pieces large enough for a harp guitar so I planned to use a 2 piece bookmatched set for the top and a third piece for the bass arm.

The seam of the bass arm

was incorporated into the design to create a lute shaped body.

We planned to use 12 super treble strings so the lowest super treble string had to be as long as possible. Locating the super treble bridge lower on the body kept the string length as long as possible.

To tune the super treble

strings, viola fine tuners would be used so that the 12 tuners

would fit close enough together.

This sketch is fairly close

to what we ended up with for the final design. There are 7 sub

bass strings, 6 melody strings and 12 super treble strings for

a total of 25 strings.

Since I had never used this arrangement of viola fine tuners for super treble strings, I built a mock up of the super treble section to see if the concept would work.

It did work! And it also helped me to visulaize the stresses on this part of the instrument so I could brace it approprately.

Now it was time to start

building...

I started the conconstruction

by cutting a frame out of baltic birch plywood. With this method

there is no assembly form required. The plywood rim becomes part

of the guitar and makes a rigid foundation for attaching all of

the tuning machines.

The walnut sides were bent

over a hot pipe then glued to the rim to crate a rigid structure.

The three piece englemann

spruce top was glued to the rim.

The walnut back is ladder

braced with spuce braces similar to a 6 string guitar.

A view from the inside showing

the bracing on the top. I have used a double X bracing.

A custom made K&K pickup

is wired to a stereo jack.

The completed body prior

to final sanding.

Once the lacquer has been

applied, the bridge is glued on and it's time to start stringing

it up- a long process for a harp guitar!

CHere is the completed guitar

ready for action.

The 2 pegheads with rosewood

veneers. The basses are wound nylon strings and the melody strings

are phosphor bronze.

The basses use Peghed geared

tuners which are light weight and hold the tuning well.

The super treble strings

are steel and start at G (1st string 3rd fret) and are tuned diatonically.

A capo for the super trebles

was requested by the customer. It's basically a heavy steel bar

that clamps on to the strings to raise the pitch by a step.

Some modifications were

needed once the the harp guitar was built. A piece of ebony was

added under the screws to keep them from digging in to the soft

spruce top. The hook or point was also added to help keep the

guitar from sliding off the players leg. It makes a big difference

and is much easier to hold.

This shows the button head

screws that anchor the strings. Basically the screws act like

zither pins to pre-tension the strings but keep the cutaway area

open so there is nothing in the way of your hand.

The viola fine tuners pull

the strings up to the final tension. The strings are color coded

to help the player find the right string.

For more information on this harp guitar please follow this link.

| home | order | prices | models | features | options | gallery | reviews | for sale |